Introduction to Repmold

In today’s competitive manufacturing environment, precision, repeatability, and engineering reliability are not optional—they are fundamental to success. Companies across automotive, medical, electronics, and consumer industries rely on high-performance molds to ensure consistent product quality and efficient production cycles.

This is where Repmold positions itself as a trusted partner. Recognized for its engineering-driven approach, advanced tooling capabilities, and commitment to customer satisfaction, Repmold delivers custom mold manufacturing solutions designed for durability, accuracy, and long-term value.

This comprehensive guide explores Repmold’s capabilities, technologies, industries served, quality standards, and future vision—helping manufacturers, procurement teams, and product developers understand why Repmold stands out in precision mold engineering.

What Is Repmold?

Repmold is a specialized manufacturing company focused on:

- Precision mold design and engineering

- High-tolerance tooling and fabrication

- Injection molding production support

- End-to-end project management

Operating at the intersection of advanced engineering and modern manufacturing, Repmold provides solutions that meet both technical performance requirements and commercial production goals.

Its services are tailored for businesses that demand:

- Tight dimensional tolerances

- Consistent repeatability

- Scalable production readiness

- Reliable delivery timelines

Leadership and Operational Philosophy

Repmold is guided by professionals with deep technical expertise in tooling, machining, and industrial manufacturing. Rather than focusing solely on volume or speed, leadership emphasizes:

- Engineering-first decision-making

- Long-term client partnerships

- Continuous process improvement

- Investment in modern manufacturing technologies

This philosophy ensures every project aligns with quality, durability, and measurable production efficiency.

History and Industry Evolution

Repmold was established to address a growing need for reliable, high-precision mold manufacturing in industries where even minor deviations can lead to costly failures.

Key Development Milestones

- Formation focused on specialized industrial tooling

- Expansion into multiple regulated and high-performance sectors

- Integration of CAD/CAM design and CNC machining technologies

- Ongoing enhancement of quality assurance and inspection systems

Over time, Repmold evolved from a tooling supplier into a full-service engineering and mold production partner, capable of supporting projects from concept through mass production.

Core Manufacturing Capabilities

Repmold’s strength lies in its end-to-end manufacturing ecosystem, allowing clients to streamline development with a single trusted partner.

Custom Mold Design and Engineering

Every successful mold begins with precision engineering. Repmold’s design process includes:

- 3D CAD modeling and digital simulation

- Design for Manufacturability (DFM) analysis

- Cycle-time and material-flow optimization

- Micron-level tolerance planning

This reduces redesign costs, accelerates production readiness, and improves final product reliability.

Tooling and Mold Fabrication

Tooling durability directly impacts production efficiency and lifecycle cost. Repmold manufactures:

- Single-cavity and multi-cavity molds

- Complex industrial tooling systems

- High-volume production molds

- Tight-tolerance precision components

Common materials include hardened tool steels and specialty alloys engineered to withstand hundreds of thousands to millions of production cycles with proper maintenance.

Injection Molding Production Support

Beyond tooling, Repmold assists with injection molding execution, ensuring:

- Dimensional consistency

- Superior surface finishes

- Scalable production capacity

- Stable process control

This makes Repmold suitable for prototype validation, pilot runs, and full-scale manufacturing.

Industries Served

Repmold supports a wide range of sectors with distinct technical and regulatory demands.

Automotive

- Heat-resistant precision components

- Structural durability requirements

- Tight dimensional tolerances

Medical and Healthcare

- Clean, controlled manufacturing processes

- High repeatability and traceability

- Compliance-focused production standards

Consumer Products

- High-quality aesthetic finishes

- Cost-efficient large-volume production

- Rapid tooling turnaround

Industrial Manufacturing

- Heavy-duty tooling durability

- Long service life under stress

- Performance-critical geometries

Electronics and Technology

- Micro-precision molds

- Complex miniature components

- Advanced material compatibility

Serving diverse industries strengthens Repmold’s engineering versatility and problem-solving depth.

Technology and Innovation

Repmold continuously invests in state-of-the-art manufacturing technology to maintain precision and competitiveness.

Key Technological Assets

- Advanced multi-axis CNC machining centers

- Integrated CAD/CAM engineering workflows

- High-precision metrology and measurement systems

- Automated and digitally monitored production support

These systems enable tolerances as tight as ±0.01 mm or better, essential for high-performance industrial applications.

Innovation at Repmold is treated as a continuous evolution, not a one-time upgrade.

Quality Control and Compliance

Quality assurance is embedded across the entire Repmold workflow.

Quality Practices Include

- Multi-stage in-process inspections

- Dimensional verification using precision metrology

- Final validation audits before shipment

- Traceable documentation across production stages

Internal systems align with international quality management principles, reducing defect risk and improving customer confidence.

Competitive Advantages

Repmold differentiates itself in a crowded market through:

- Engineering-driven project execution

- Exceptional tooling precision and repeatability

- Flexible production scalability

- Transparent client communication

Many customers choose Repmold for long-term operational reliability, not just short-term pricing.

Sustainability and Responsible Manufacturing

Modern manufacturing must balance performance with environmental responsibility.

Repmold supports sustainability through:

- Optimized material utilization

- Reduced machining waste

- Energy-efficient production strategies

These practices help clients meet environmental expectations and regulatory trends without compromising quality.

Client Workflow and Project Lifecycle

Repmold follows a structured, transparent development process:

- Initial consultation and technical assessment

- Engineering design and simulation validation

- Precision tooling fabrication

- Testing, inspection, and quality approval

- Production launch and delivery support

Clear communication and realistic timelines ensure predictable project outcomes.

Global Reach and Supply Chain Support

Repmold serves both domestic and international manufacturers, offering:

- Coordinated logistics and delivery planning

- Consistent quality across regions

- Adaptability to global production standards

This makes Repmold a strong partner for globalized manufacturing operations.

Repmold vs. Other Mold Manufacturers

Compared with many competitors, Repmold provides:

- Deeper engineering involvement early in projects

- Higher tooling consistency and lifespan

- Reduced downtime and rework

- Stronger long-term cost efficiency

Rather than prioritizing speed alone, Repmold balances precision, durability, and ROI.

Performance Benchmarks and Capabilities

Typical industrial benchmarks associated with Repmold projects include:

- Mold lifecycles reaching hundreds of thousands to over one million cycles

- Precision tolerances near ±0.01 mm

- Support for prototype through mass production

- Experience in high-regulation industries

These metrics reflect industrial-grade manufacturing performance.

Future Vision and Growth

Repmold’s long-term strategy focuses on:

- Advanced automation and smart manufacturing

- Expanded high-performance material capabilities

- Digital process optimization

- Stronger international partnerships

The goal is clear: remain a trusted, innovation-driven precision manufacturing partner in a rapidly evolving global market.

Why Choose Repmold?

Repmold is ideal for organizations that value:

- Precision over shortcuts

- Reliability over uncertainty

- Partnership over transactional supply

From startups to multinational manufacturers, Repmold delivers engineering confidence and production excellence.

Frequently Asked Questions

What does Repmold specialize in?

Precision mold design, tooling fabrication, and injection molding support.

Which industries benefit most?

Automotive, medical, electronics, consumer goods, and industrial manufacturing.

Are molds custom-engineered?

Yes—solutions are tailored to each project’s technical requirements.

How is quality ensured?

Through engineering validation, advanced machining, and strict inspection processes.

Can Repmold support high-volume production?

Yes, from prototyping to full-scale manufacturing.

Final Thoughts

Repmold represents the qualities modern manufacturers seek in a tooling partner: precision, durability, innovation, and trust. By combining advanced engineering with disciplined manufacturing processes, the company delivers molds designed for consistent performance and long operational life.

For organizations pursuing high-reliability production and measurable long-term value, Repmold stands as a compelling partner in precision mold manufacturing.

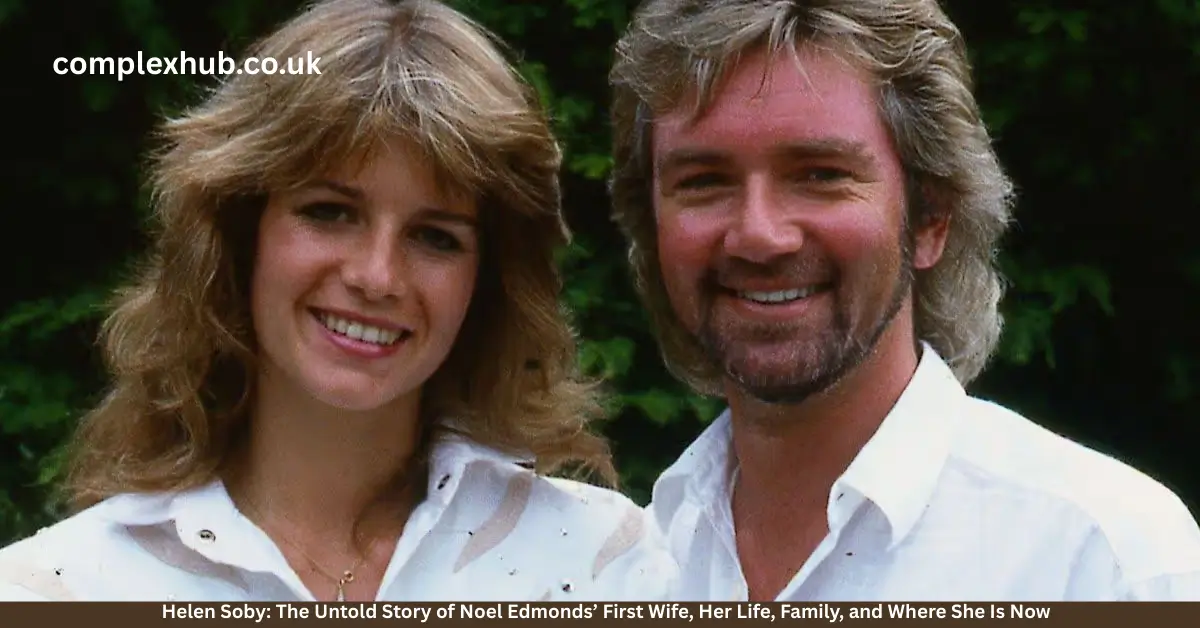

Read More :- Helen Soby